|

Neue Herbold offers a complete program for the size reduction (granulators, grinders, pipe-granulators, profile-granulators, pulverizers, fine-grinders, screw-shredders, bale-breaker, hammer mills, shredders, polystyrene-shredders, guillotines, complete washing-lines) and preparation of plastic waste from production and plastic waste collection points.

For special application projects they can provide indivdual taylor made machines and systems designed specifically for the customers needs. Included in this vast equipment spectrum are machines (hammer mills, bale breaker, guillotines) to recycle computer hardware and software, insulation material etc.

Through experience and engineering “know how“, NEUE HERBOLD can supply complete “turn key“ systems as well as individual machines for all areas of the plastic industry.

Plastic Size Reduction:

|

Machine Type

|

Rotor diameter (mm

|

Working Width (mm)

|

|

1 shaft shredder type ERM 1600

|

600

|

1600

|

|

Machine type

|

Diameter of the Grinding Chamber (mm)

|

|

2 shaft shredder ZRM 1100/2

|

1030/800

|

|

2 shaft shredder ZRM 1100/4

|

1030/1550

|

Polystyrene Shredder

Application

Neue Herbold - Polystyrene shredders RL Series are used for size reduction of EPS and PUR Foam.

Technique

Unlike the granulators for size reduction of plastics, the RL shredder operates with a cross beater rotor, without rotor knives, in order to maintain the cell structure of the material.

The granulate size is determined by the distance between the cutting instruments as well as the screen hole size.

Advantages

- low wear and tear costs due

to knifeless operation

- high throughput rates

- ultimate final product

Guillotine

Applications

Neue Herbold GS series guillotines are used for the pre-size reduction of monofilament bales such as from fibre, bands or tapes, tacky film packages, extremely large lumps, start-up purgings or rubber bales.

Advantages

- precise adjustment of the vertical

knife

- double sided frame construction

- vertical knife complete enclosed for

safety

- fully adjustable stroke, knife speed

and cutting pressure

- double sided knife channel

- two cylinder operation to insure

true knife operation

Granulators:

Granulators LM Series PDF

Granulators SM Series PDF

Pulverizers ZM Series PDF

Hammer Mills

Applications

Neue Herbold HM series hammer mills offer flexibility in their application range. Through the installation of material oriented rotor milling hammers tools various types of brittle plastics such as electronic scrap, wood scrap, and organic insulation material.

Design

Neue Herbold HM series hammer mills are designed and equipped highly wear resistant cutting instruments (hammers and hammer bars). The bearings of the rotor shaft are mounted within solid steel housings (not castings) which offer more reliable service and eliminate any chance for the housings to crack or break under heavy shock loads. As opposed to flanged mounted bearings, outboard mounting prevents dust/fines from fouling the bearing nor grease from contaminating the granulate. Outboard mounting provides for a quieter and cooler. The totally welded housing can also be equipped with replaceable wear plates when operating with high impact or abrasive material.

Advantages

- flexibility in their application

range

- heavy duty design

- reduced space requirement

due to compact design

- energy-saving size reduction

- extremely high through put

rates

- easy cleaning due to clam

shell opening characteristics

- reduced down time for

hammer replacement.

Special Waste Recycling:

|

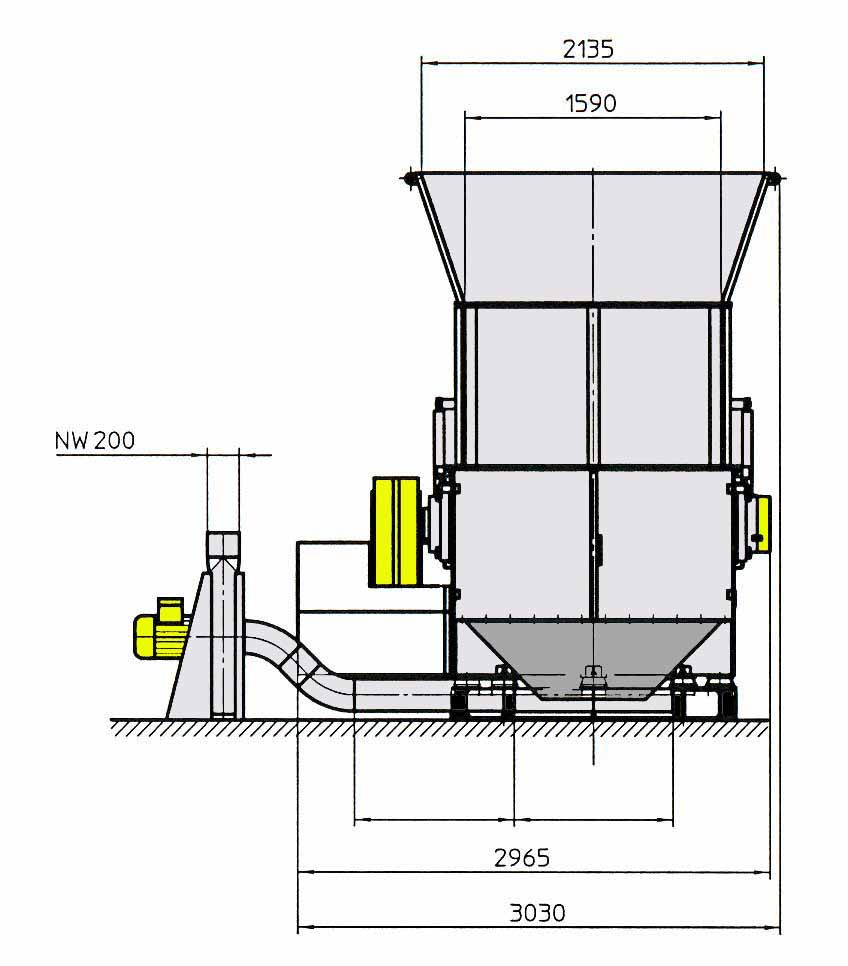

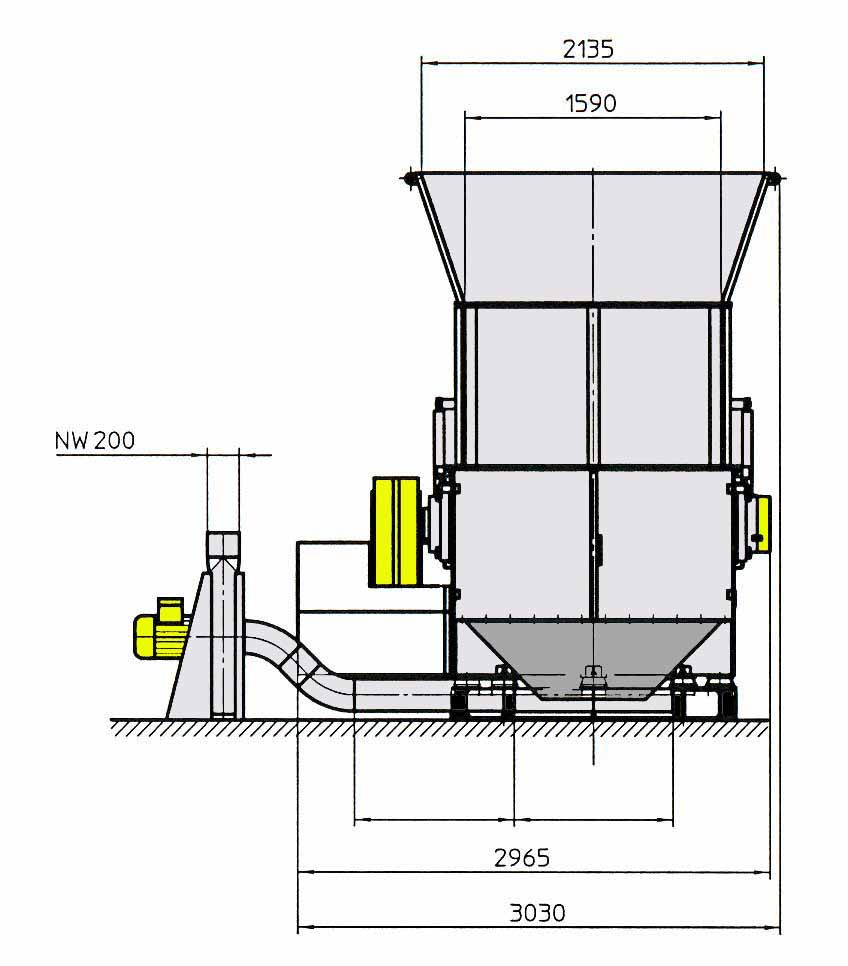

One Shaft Shredder

Application Neue Herbold - One Shaft Shredders ERM Series are mainly used for pre-cutting of bales, scrap tires, energetic utilization of waste as well as post consumer waste.

Technique

Neue Herbold - One Shaft Shredders are equiped with a slow operation rotor. A hydraulically controlled ram feeder transports the feeding material into the cutting area of the rotor. Once the ram feeder has reached its final position it returns automatically to its starting position.

Advantages

- automatic reverse operation

- exchangeable knife supports

- exchangeable cutting heads

(bolted/plug-in connection))

Two Shaft Shredders

Application

Neue Herbold - Two Shaft Shredders ZRM Series are used for pre-cutting of large amounts of material, or bulky materials like film, scrap tires, random plastic waste or drums

Advantages

- automatic reverse operation

- low wear costs

Screw Shredder

Applications Neue Herbold SB screw shredder / bale breaker is engineered and manufactured with a two fold main function. Its heavy duty design makes it ideal for voluminous materials such as wood pallets, cable drums, sheets of insulation, porous building blocks and when used in the PET bottle size reduction can easily and effectively achieve a cluster free break down of PET baled bottles. Through this extremely effective method of bale breakdown the down stream bottle separation process will be far more precise.

Advantages

- flexibility in application range

- heavy duty design

- energy-saving size reduction

- low noise level

- extremely high through put rates

- reduced down times

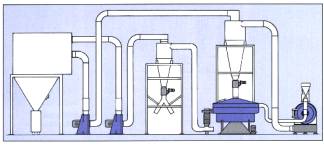

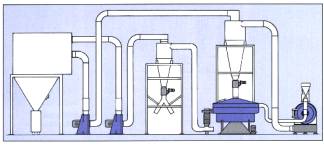

Fine Grinders/Pulverizers

Applications

Neue Herbold ZM series pulverizers are designed for the pulverizing of mid-hard, brittle to high impact plastics that require the final material to be in powder form. Typical applications are PE, PVC, PC and other various types of plastics. The required pulverizer input material must be in a granulate form with a maximum size of 6-8 mm (1/4-5/16 in.).

Design

The ZM series pulverizer is a extremely high out put unit can be supplied with automatic temperature control. The material to be pulverized is vibro feeder fed into fixed and high speed rotating pulverizer discs. In conjunction with a integrated inner disc that material is centrifically forced through the pulverizer discs to the outer chamber for discharge with a down stream material transport system. Neue Herbold ZM series pulverizers operate without a screening machine. The specific final powder size is dependent on the teeth configuration and the adjustable gap between the pulverizer discs. In the event that the application requires a maximum particle size, a screening machine can be easily integrated into the system.

Advantages

- extremely high through put rates

- minimal thermal material stress

- longer disc life and reduced

re-sharpening costs

- quick and easy disc adjustment

and replacement

- cost effective operation

For more information on Special Waste Recycling or other products featured on this page please follow the links below:

NEUE HERBOLD - VDMA PET Recycling NEUE HERBOLD - VDMA PET Recycling

NEUE HERBOLD - Range of Products NEUE HERBOLD - Range of Products

|